Introduction

Clinker vs cement export cost is one of the most critical factors for buyers and importers in 2025. For importers in the GCC, Africa, and South Asia, the choice between clinker export and cement export often comes down to price per ton, logistics, and flexibility.

In 2025, as mega-projects rise across Saudi Arabia, the UAE, Oman, and African nations, demand for cement materials is climbing—but so are cost pressures. Knowing whether to import clinker (semi-finished material) or finished cement can make the difference between profit and loss for distributors and contractors according to Global Cement’s 2025 Market Report

This blog provides a clear clinker vs cement export cost comparison, along with logistics considerations, regional pricing trends, and insights for buyers who want the best deal in 2025.

What Is Clinker and Why Export It?

Clinker is the semi-finished product formed when limestone and clay are heated in a kiln. These marble-sized nodules are later ground with gypsum to make Portland cement. ASTM C150 Portland Cement Standard sets global requirements for clinker and cement exports.

Why many buyers prefer clinker:

- Lower freight costs – clinker is shipped in bulk without bags.

- Flexible production – importers grind clinker locally, producing different cement grades.

- Tariff benefits – some countries tax finished cement higher than clinker.

- Storage advantage – clinker can be stockpiled for months without quality loss.

Example: In the UAE, several grinding units import clinker from Iran and India, then process it locally, reducing costs while keeping value-added jobs in-country.

In the clinker vs cement export cost debate, clinker remains the more affordable choice for large buyers.

What Is Cement Export?

Cement is clinker that has already been ground, blended, and packaged. It can be exported as:

- Bulk cement – pumped into special ship holds or silos.

- Bagged cement – packed in 50kg or jumbo bags.

While bagged cement is more expensive, many buyers accept the higher clinker vs cement export cost because it saves on local grinding investment.

Why some buyers prefer cement:

- Ready-to-use – no grinding facilities needed.

- Lower capital investment – importers can sell cement directly.

- Smaller buyers benefit – retail distributors and contractors can resell bagged cement immediately.

Example: African importers like Kenya and Ghana often prefer cement bags because small distributors lack clinker grinding capacity.

Clinker vs Cement Export Cost – Price Comparison in 2025

One of the biggest deciding factors for buyers is price per ton.

Price Table – 2025 Estimates

| Product | FOB Iran Price (2025) | CIF UAE/Oman | CIF Africa |

|---|---|---|---|

| Clinker | $28 – $32 / ton | $34 – $40 / ton | $36 – $42 / ton |

| Cement | $40 – $55 / ton | $48 – $65 / ton | $55 – $70 / ton |

This table clearly shows how the clinker vs cement export cost gap remains significant in 2025, often influencing large-scale procurement decisions.

Key Insights:

- Clinker is 25–35% cheaper than cement per ton.

- Cement requires extra packaging, labor, and transport, driving up costs.

- For large buyers (ports, distributors), clinker offers better long-term margins.

- For small buyers (retail, local contractors), cement’s higher cost is justified by convenience.

Logistics Costs Affecting Clinker vs Cement Export Cost

The real difference in clinker vs cement export often lies in logistics:

- Clinker:

- Shipped in bulk carriers.

- Loaded directly into ship holds → cheaper handling.

- Less packaging waste.

- Cement:

- Needs 50kg bags, jumbo bags, or bulk cement tankers.

- Higher port handling fees.

- More labor-intensive loading & unloading.

On average, cement logistics cost 15–20% more than clinker per shipment. Packaging and port handling add another layer to the clinker vs cement export cost, making cement consistently 15–20% more expensive.

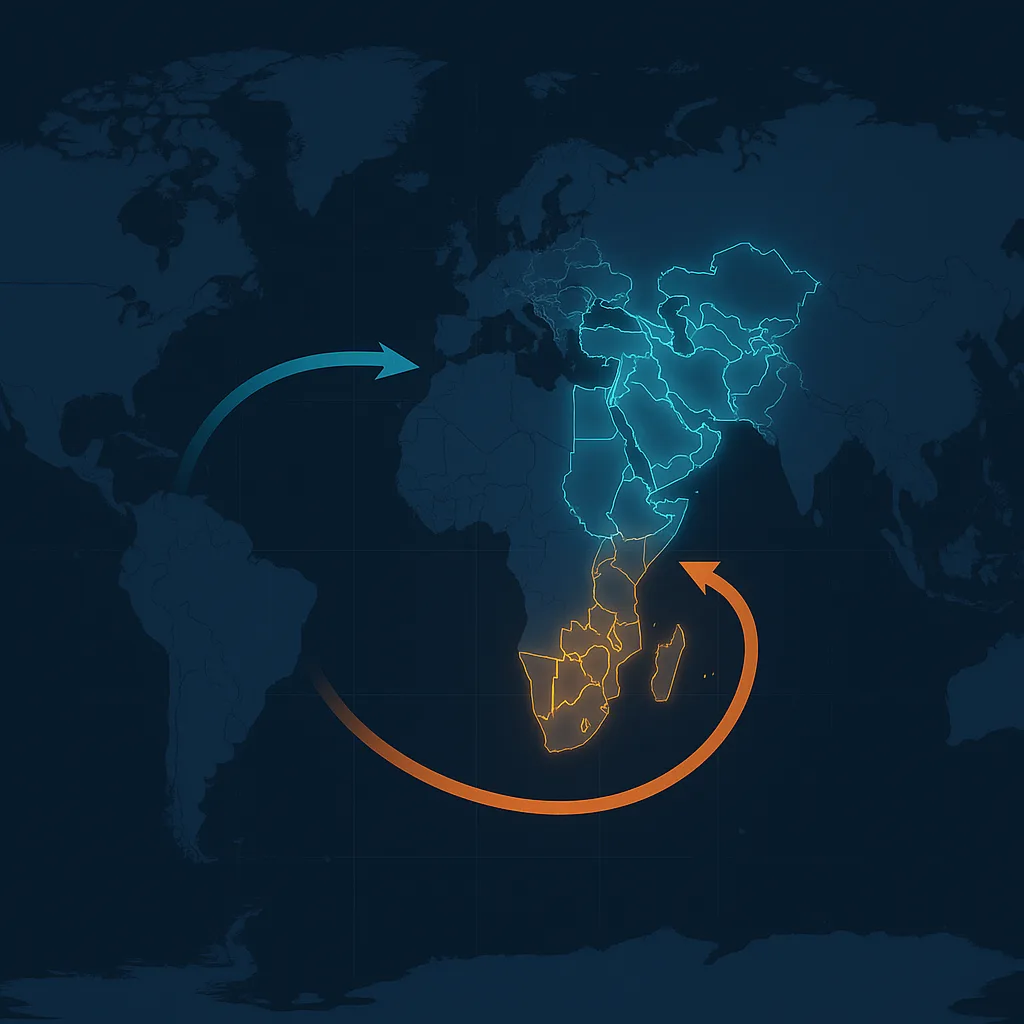

Market Demand: GCC vs Africa

GCC Market

- GCC countries (UAE, Oman, Qatar, KSA) prefer clinker imports.

- Allows local grinding to adjust quality to project needs.

- Aligns with national strategies to keep value-added jobs local.

Africa Market

- Many African nations (Kenya, Ghana, Tanzania) prefer cement imports.

- Lack of grinding infrastructure makes cement bags more practical.

- Higher price per ton is offset by immediate usability.

- In Africa, the clinker vs cement export cost difference often determines whether buyers import clinker for grinding or finished cement for direct use.

Profit Margins & Buyer Considerations

Choosing clinker vs cement is not just about FOB price—it’s about long-term profit margins.

- Clinker saves money upfront but requires investment in grinding plants.

- Cement costs more but is a plug-and-play product for smaller buyers.

For large-scale importers (ports, government buyers, mega-project contractors):

Clinker is usually the smarter choice.

For small-to-medium distributors (retail-focused businesses):

Cement import makes more sense. For distributors, evaluating clinker vs cement export cost is essential to calculate long-term profitability.

Karbin Cement’s Advantage

At Karbin Cement, we offer both clinker and cement exports to meet diverse buyer needs.

✔️ Bulk clinker shipments (FOB or CIF)

✔️ Bagged and jumbo bag cement for retail markets

✔️ ASTM and ISO certified products

✔️ Logistics advantage via Chabahar Port, reducing freight to GCC and Africa

We help clients minimize their clinker vs cement export cost with optimized logistics and reliable supply.

FAQ

Q1: Which is cheaper, clinker or cement?

Clinker is cheaper by 25–35% per ton compared to cement.

Q2: Why do GCC countries import clinker?

To grind it locally, reduce costs, and customize cement grades.

Q3: Can clinker be stored longer than cement?

Yes, clinker can be stored for months without losing quality. Cement must be used quickly to avoid deterioration.

Q4: What is the average clinker export price in 2025?

FOB Iran: $28–$32 per ton. CIF GCC: $34–$40 per ton.

Conclusion

The clinker vs cement export cost comparison in 2025 shows a clear pattern:

- Clinker offers lower prices, simpler logistics, and better margins for large buyers.

- Cement provides convenience, immediate use, and easier distribution for smaller markets.

As construction demand continues to grow across the GCC and Africa, both products will remain vital. However, importers must carefully assess their infrastructure, buyer network, and long-term goals before deciding.

Looking for a reliable clinker or cement supplier? Contact Karbin Cement today to request a customized export quote.