Introduction

In 2025, CEM I 42.5N cement GCC projects are setting new benchmarks for quality and durability. CEM I 42.5N cement GCC 2025 has become a construction essential across the Middle East, powering the massive infrastructure boom transforming the Gulf region. From Saudi Arabia’s futuristic NEOM megacity to Dubai’s sustainable smart districts and Oman’s rapid industrial expansion, builders and engineers are demanding a cement that can handle scale, speed, and climate extremes.

That’s where CEM I 42.5N comes in — a globally recognized, high-performance Portland cement known for its superior strength, consistency, and versatility. In 2025, it remains the preferred choice for GCC mega projects that require dependable materials meeting strict engineering standards.

At Karbin Cement, we specialize in producing and exporting CEM I 42.5N cement that complies with EN 197-1 European standards and GCC construction codes, ensuring every shipment delivers unmatched quality and reliability.

What is CEM I 42.5N Cement?

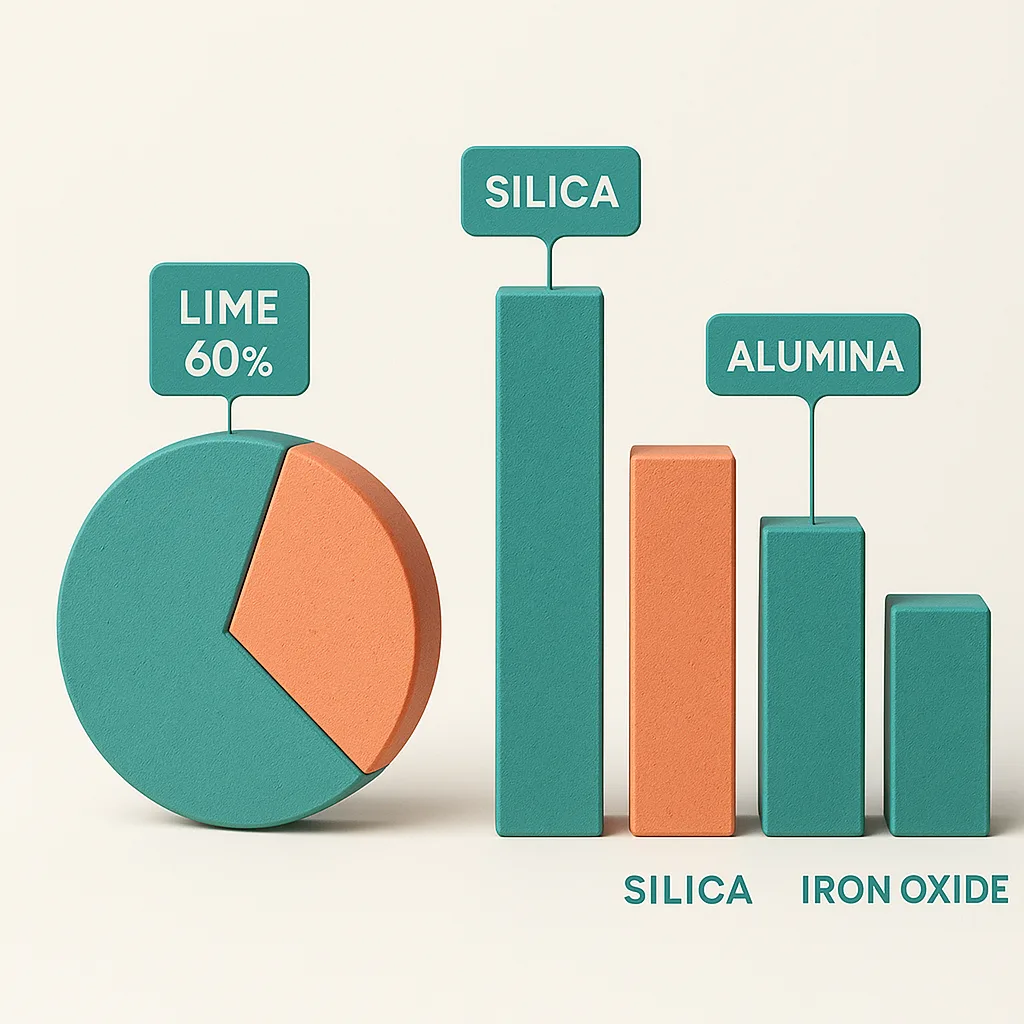

CEM I 42.5N is a pure Portland cement, meaning it is composed primarily of clinker and a small amount of gypsum, without additives such as fly ash or slag. The “42.5” refers to its minimum compressive strength (in MPa) after 28 days, while the “N” stands for normal early strength.

This cement is ideal for projects requiring:

- Rapid early-stage strength development.

- High final compressive strength.

- Durability under variable environmental conditions.

Its chemical composition — rich in lime (CaO), silica (SiO₂), alumina (Al₂O₃), and iron oxide (Fe₂O₃) — ensures uniform hydration and long-term stability.

View complete technical data and quality certifications on Karbin Cement Product Specifications.

Reference: World Cement Technical Overview.

Why CEM I 42.5N Is Perfect for GCC Construction Conditions

The GCC climate presents one of the toughest environments for concrete performance — intense heat, high humidity, and saline air near coastal regions. Standard cement grades often struggle under these conditions, leading to cracking and reduced durability.

CEM I 42.5N overcomes these challenges through:

- High heat resistance — maintains strength even in 45°C+ temperatures.

- Rapid setting time — ideal for quick-turnaround projects.

- Excellent chloride resistance — protects rebar in marine and coastal structures.

This makes it perfect for:

- Skyscrapers and high-rise buildings (UAE, Qatar).

- Bridges, tunnels, and foundations (Saudi Arabia, Oman).

- Industrial zones and ports (Bahrain, Kuwait).

At Karbin Cement Sustainability Page, we ensure all production meets GCC green building standards, minimizing carbon footprint while maximizing strength.

External source: GCC Construction Outlook 2025 – Statista.

Key Technical Advantages of CEM I 42.5N

1. High Compressive Strength

Engineers prefer CEM I 42.5N cement GCC for its reliable performance under extreme climate conditions. CEM I 42.5N achieves over 42.5 MPa within 28 days, providing the structural integrity required for heavy-duty foundations, bridges, and load-bearing elements.

2. Rapid Setting Time

Projects in hot climates often demand fast formwork removal and accelerated construction cycles. This cement’s controlled fineness allows faster setting without sacrificing strength.

3. Excellent Durability

Its dense microstructure gives it superior resistance to sulphates and chlorides, extending the lifespan of buildings and infrastructure exposed to harsh conditions.

4. Consistent Quality

Every batch of Karbin Cement’s CEM I 42.5N undergoes lab testing for fineness, setting time, and strength, ensuring uniform performance across projects.

5. Compatibility with Additives

CEM I 42.5N works seamlessly with fly ash, slag, silica fume, and chemical admixtures, allowing engineers to optimize mixes for specific project requirements.

Comparison – CEM I 42.5N vs Other Grades

When comparing grades, CEM I 42.5N cement GCC consistently provides better cost efficiency. When comparing CEM I 42.5N with other Portland cement grades, it strikes the perfect balance between strength, workability, and cost — ideal for GCC mega projects.

| Property | CEM I 32.5N | CEM I 42.5N | CEM I 52.5N |

|---|---|---|---|

| Compressive Strength | Moderate | High | Very High |

| Setting Time | Standard | Faster | Similar |

| Durability | Good | Excellent | Excellent |

| Price (FOB Iran) | $36–40 | $38–44 | $45–50 |

| Ideal Use | Residential | Infrastructure & Mega Projects | Specialized Works |

Contractors prefer CEM I 42.5N cement GCC 2025 because it delivers the performance of premium grades without the high cost of 52.5N.

Request the latest export pricing via Karbin Cement Request Quote.

Price data reference: Trading Economics Cement Prices.

Why Karbin Cement’s CEM I 42.5N Leads the Market

Karbin Cement stands out among Iranian exporters by combining technical precision, quality control, and logistics expertise — a complete solution for GCC clients.

Our Competitive Advantages

- ISO 9001 and EN 197-1 certified production.

- Modern manufacturing lines ensuring particle size consistency.

- Monthly capacity exceeding 100,000 MT ready for export.

- Quick shipping routes via Bandar Abbas and Chabahar.

- Comprehensive documentation: Certificate of Origin, Quality Certificate, and SGS testing reports.

Our Export Support Team ensures smooth customs procedures and shipment coordination.

External reference: GCC Standardization Organization.

Use Cases – CEM I 42.5N in GCC Mega Projects

1. Foundations for NEOM and Red Sea Projects (Saudi Arabia)

Large-scale foundations require consistent high strength and resistance to saline groundwater — CEM I 42.5N performs flawlessly here.

2. Precast Elements in Lusail City (Qatar)

The fast-setting nature of this cement allows quicker mold turnover, improving efficiency in precast manufacturing plants.

3. High-Rise Towers in Dubai and Abu Dhabi

Used for core walls, slabs, and columns, CEM I 42.5N ensures structural integrity in skyscrapers exceeding 200 meters.

4. Marine Infrastructure in Oman

CEM I 42.5N’s chloride resistance makes it ideal for port construction, breakwaters, and seawalls.

Our long-term Karbin Cement Partnerships supply consistent volumes across these GCC mega projects.

CEM I 42.5N Cement GCC 2025 – Sustainability and Future Demand

The demand for CEM I 42.5N cement GCC 2025 will continue growing as governments focus on sustainable, large-scale infrastructure.

Karbin Cement leads by:

- Reducing CO₂ emissions via optimized kilns.

- Utilizing local raw materials for lower transportation impact.

- Implementing eco-friendly packaging for exports.

By aligning with GCC sustainability goals, Karbin Cement ensures long-term partnerships with environmentally conscious developers.

Final Thoughts – The Smart Choice for GCC Builders

Karbin Cement remains the leading producer of CEM I 42.5N cement GCC trusted across major regional developments. As GCC nations expand their cities and invest in record-breaking infrastructure, one cement grade remains at the core of progress — CEM I 42.5N cement GCC 2025.

Its combination of strength, durability, consistency, and cost-efficiency makes it the top choice for large-scale projects across the region.

For builders, engineers, and contractors seeking a dependable supplier, Karbin Cement offers:

✅ Certified quality under EN 197-1 standards.

✅ Competitive pricing and quick export logistics.

✅ Technical support and full documentation for every shipment.

Contact Karbin Cement today to discuss your project needs and receive a tailored CEM I 42.5N quotation for 2025.